Five Major Misconceptions in Selecting Drag Chain Cables

Misconception 1: Drag Chain Cables (High-Flexibility Cables) = Soft Cables

Incorrect View: The term FLEX is often misconstrued as referring to softness, which is a significant misunderstanding in the context of drag chain cables.

In this case, FLEX denotes flexibility, not softness. A flexible cable is one that is pliant and elastic, not soft.

Over 80% of drag chain cable failures are due to copper conductor breakage, which occurs because the metal fatigue reaches a critical point and causes the conductor to break.

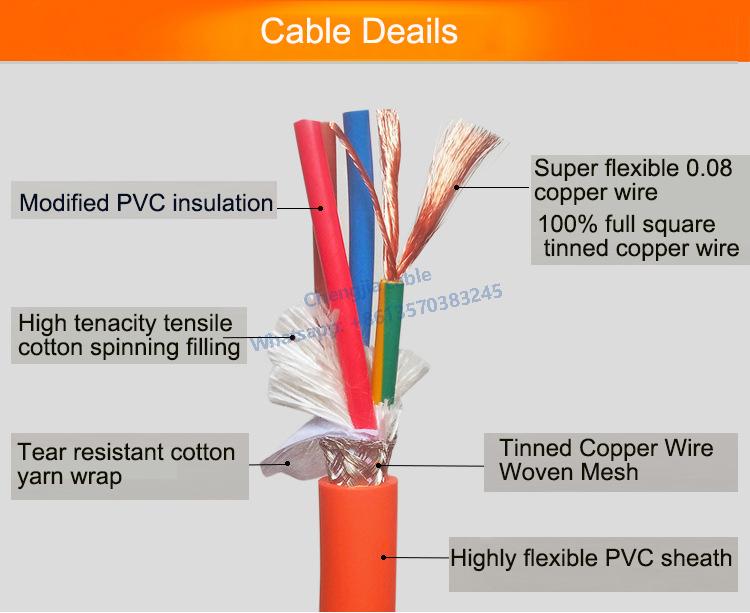

The hardness of copper conductors can only be adjusted by changing their diameter, while the softness of the cable mainly depends on the hardness of the insulation material. The overall hardness of the cable largely depends on the insulation material.

Due to the specific application of drag chain cables, the hardness of the insulation material and conductor must be relatively similar to ensure even stress distribution along the cable and extend its lifespan. This is a fundamental design principle for drag chain cables.

Misconception 2: Drag Chain Cables (High-Flexibility Cables) Are Better with Thinner Conductors

Incorrect View: Some manufacturers claim that thinner conductors are better for drag chain cables, with some even advertising conductors as thin as 0.05mm or even 0.03mm (compared to a hair thickness of 0.07mm).

Thinner copper conductors have weaker tensile strength and are more likely to break under stress during movement.

The diameter of the conductor should be matched to the cable's cross-sectional area; thinner is not always better. For example, a 0.2-square-mm high-flexibility signal cable may be suitable with 0.08mm diameter conductors, but a 10-square-mm high-flexibility power cable would not be appropriate with 0.08mm conductors.

While non-specialists may fall into this misconception, a professional flexible cable manufacturer should understand the correct application of conductor diameters. This highlights the importance of specialized expertise in this field.

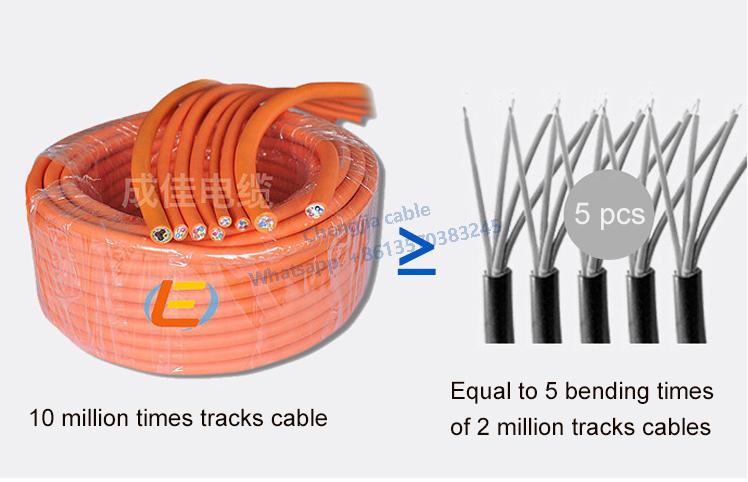

Misconception 3: Drag Chain Cables Should Only Be Evaluated Based on Bending Cycles

Incorrect View: Many salespeople focus solely on bending cycle ratings, such as 5 million, 10 million, 15 million, or more. This leads to the incorrect belief that the more flexible the cable, the higher the bending cycle rating.

Professionals understand that bending cycles depend on three key factors: bending radius, movement speed, and drag chain travel length. The lifespan of drag chain cables is closely related to these three factors. Ignoring these prerequisites and focusing only on bending cycles is irresponsible.

For instance, a cable with an outer diameter of D=8.0mm, with a standard drag chain installation bending radius >7.5D, and a speed <3 meters per second, can reach 15 million bending cycles. If the bending radius is increased to >10D while keeping speed and travel length constant, the cable's bending endurance will exceed 15 million cycles. Conversely, if the bending radius is reduced to <5D, the cable's lifespan will fall significantly below 15 million cycles. The specific application scenario, such as exposure to oil, acids, abrasion, moisture, UV, and temperature variations, also affects the cable's bending endurance.

Misconception 4: Drag Chain Cables Are Better If They Are Thicker and Heavier

Incorrect View: Many customers judge cable quality based on thickness or weight. They believe that a larger diameter and heavier cable indicate better quality, whereas a smaller diameter and lighter cable imply inferior quality.

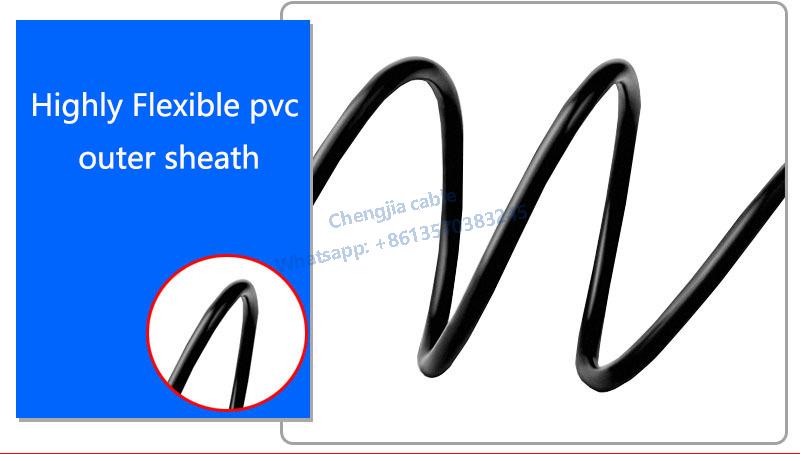

Drag chain cables need to be designed with a smaller outer diameter while still meeting electrical performance requirements. Smaller diameters reduce the bending radius requirements for installation.

Achieving the same electrical performance with a smaller diameter requires higher manufacturing precision and better materials. A smaller diameter involves using higher-quality modified materials for the sheath and insulation, without compromising on conductor quality.

Misconception 5: Drag Chain Cables That Are Difficult to Process and Assemble Are Not Good

Incorrect View: After purchasing drag chain cables, customers often need to perform processes such as stripping the sheath and insulation, tinning the conductors, attaching terminals, and assembling various connectors. Some workers may assume that cables should be as easy to process as ordinary cables to improve efficiency, even if it means avoiding the use of anti-tensile fillers.

Ordinary PVC is easy to strip but too brittle to withstand long-term mechanical stress and friction. To ensure the lifespan of drag chain cables, modified PVC or PUR materials are required. These modified materials have 1-2 times greater mechanical strength than standard PVC.

Ordinary cables are produced using extrusion processes, while drag chain cables require extrusion or semi-extrusion processes, which makes them harder to strip. Adding anti-tensile fillers necessitates an additional step to cut and clean these fillers.

Ignoring the special requirements and application scenarios of drag chain cables in favor of ease of processing can create significant safety risks and compromise the cable's performance and longevity.

Contact: Mandy Dai

Phone: +86-13570383245

E-mail: sales@flex-cables.com

Whatsapp:0086-13570383245

Add: No. 12 building, No.46,Shilou Section,Shilian Road, Panyu District,Guangzhou, Guangdong,China

We chat