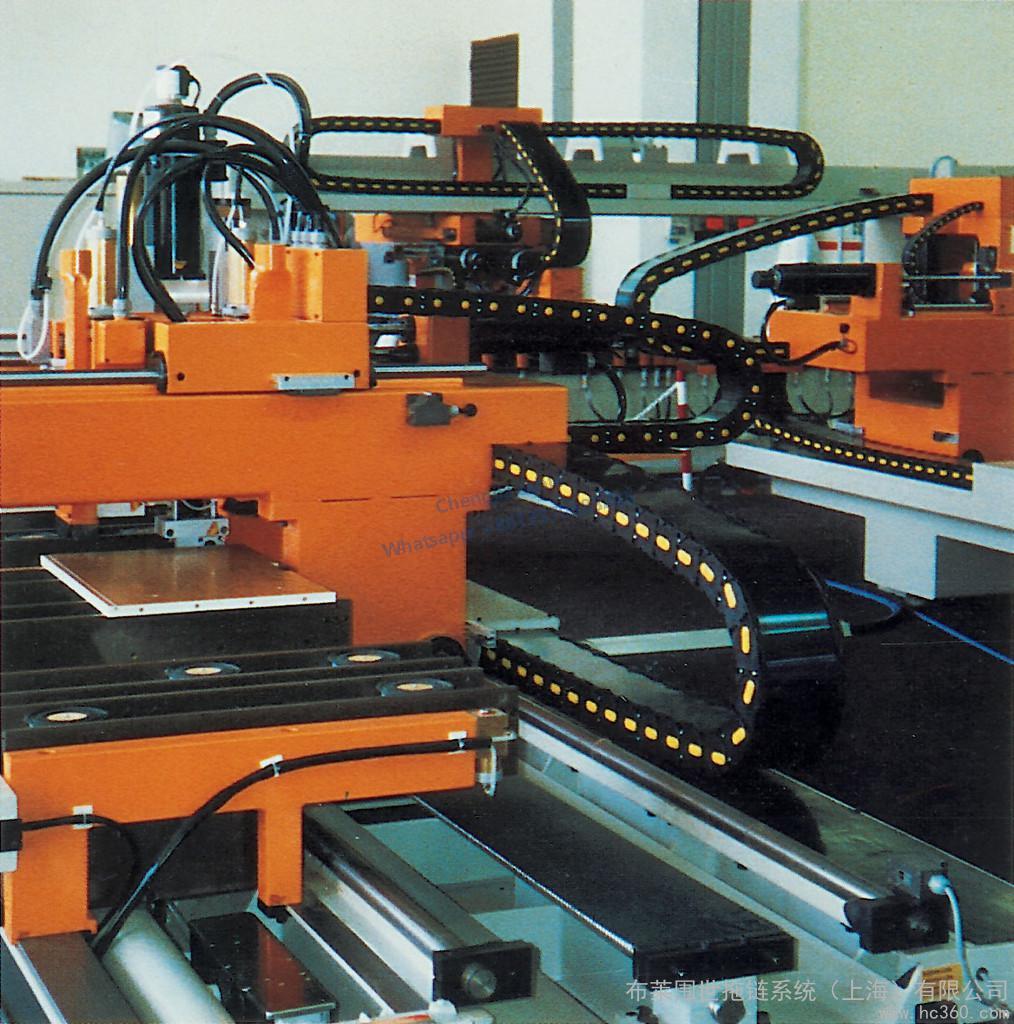

What are the standards for selecting high-flexibility drag chain cables? When it comes to high-flexibility cables, most people are somewhat familiar, but they may fall into some misconceptions when purchasing high-flexibility cables for drag chain systems. High-flexibility cables are the preferred cables for power transmission and signal transmission in drag chain motion systems, also known as drag chain cables, towline cables, moving cables, robot cables, etc. The sheathing is usually made of low-viscosity, flexible, and wear-resistant materials to reduce the wear rate of the cable during continuous back-and-forth movement. So how should one choose high-flexibility drag chain cables, and what are the standards for selecting them?

Firstly, ordinary sheathed flexible cables cannot be used in drag chains:

Cables with design defects: Combinations of core wires with inconsistent outer diameters that have not been meticulously designed can lead to uneven stress on the cable at various points, resulting in a significantly reduced lifespan during use.

To enhance flexibility and mechanical strength, drag chain cables generally require auxiliary functional characteristics; simply reducing the stranding pitch like conventional cables will not work.

The external sheath material: Generally, materials with slightly stronger shrinkage are beneficial to the cable's lifespan; regular PVC does not meet the standards for drag chain high-flexibility cable sheaths.

Besides these points, there are additional considerations in selecting high-flexibility cables for drag chains:

Current Carrying Capacity

The current carrying capacity refers to the maximum current value the cable can withstand during use. It is important to check whether the cable's structural design incorporates derating. Additionally, review the insulation resistance and voltage rating at the cable terminals to ensure compliance with application requirements.

Cable Structural Dimensions

Different environments often require different cable sizes. A larger cable size generally indicates a higher current carrying capacity.

Impedance Matching

To achieve effective signal transmission, cables typically have impedance requirements. This is particularly critical in environments with significant magnetic interference. If the cable's impedance does not match, it may cause intermittent signal transmission or, in severe cases, signal reflection, preventing proper signal reception.

Shielding

To enhance signal transmission, a shielding layer is added to the cable's insulation to protect against external environmental interference. High-flexibility cables for drag chains generally use braided shielding; for areas with strong interference signals, double-layer or multi-layer shielding may be employed.

Reliability

The reliability of a cable refers to its safety. High-flexibility cables use surface or point contact methods to ensure tighter connections, enhancing reliability during use.

Our main products include: ultra-high flexibility (PUR/50 million cycles), super high flexibility (20 million cycles), high flexibility (10 million cycles), and standard flexibility (5 million cycles) PVC sheathed drag chain cables (for data transmission, control, power), among other specialized cables. Our flexible cables feature independently developed production processes that match the durability of leading brands from Germany and Japan and can serve as complete replacements. We have ample stock, a full range of specifications, and a large inventory!

Contact: Mandy Dai

Phone: +86-13570383245

E-mail: sales@flex-cables.com

Whatsapp:0086-13570383245

Add: No. 12 building, No.46,Shilou Section,Shilian Road, Panyu District,Guangzhou, Guangdong,China

We chat