The differences Between Drag Chain Cables and Flexible Cables

When choosing a flexible drag chain cable, people might mistakenly think that any flexible cable can be used for drag chains. Thus, silicone cables and other soft cables like RV, RVV, RVVP, and RVSP are sometimes used for drag chains. However, mere flexibility is not enough to meet the high flexibility requirements for drag chain cables. Additional durability is required. During movement, cables need to endure stress, tensile forces, abrasion, small bending radii, and twisting, which are important mechanical properties.

In low-frequency, large bending radius environments, standard flexible cables may not show issues immediately. However, in environments where bending is frequent and mechanical strength is high, there are significant differences between standard cables and drag chain cables. When a drag chain cable frequently moves, standard cables like silicone cables cannot meet these requirements effectively, leading to wear and breakage of the internal conductors, which can cause equipment malfunction.

Differences Between Drag Chain Cables and Standard Cables:

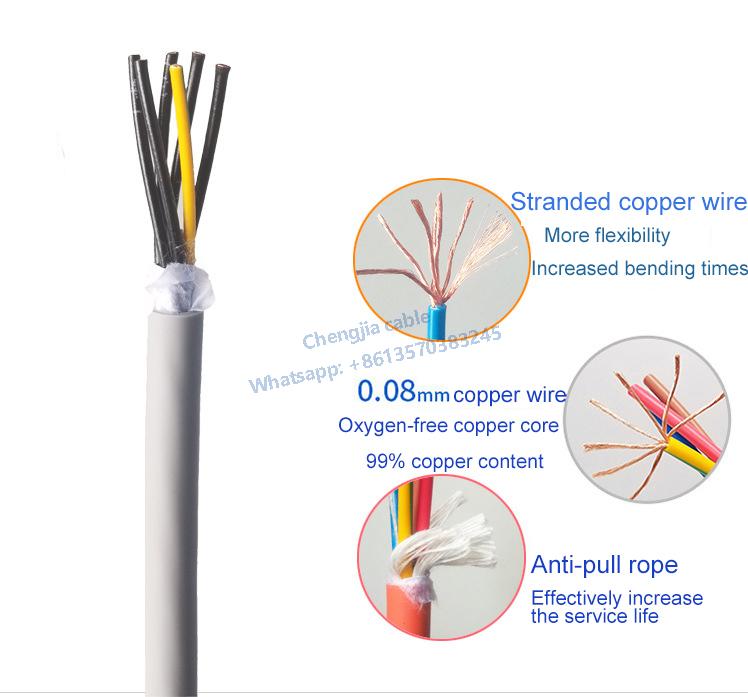

Conductor Characteristics: Drag chain cables often use finer conductors (around 0.5-0.08 mm) made from multiple strands of high-purity copper to ensure stable physical and electrical properties. In contrast, standard flexible cables may use thicker or less specialized conductors, which can impact their performance under stress.

Insulation Quality: Drag chain cables have high concentricity and uniform insulation thickness, tested through rigorous bending trials. This ensures durability under constant movement. Standard cables may lack this level of precision and protection.

Cable Construction: Drag chain cables typically employ stranded construction to withstand mechanical stress, twisting, and bending. This design helps release internal stress and extends the cable’s lifespan. Ordinary cables may not be built to handle such mechanical strain.

Stretch Requirements: Drag chain cables often incorporate materials like nylon or Kevlar for enhanced tensile strength. Standard cables usually do not have these reinforcing materials, making them less suitable for high-stress environments.

Abrasion Resistance: Drag chain cables are designed with high abrasion resistance, often using TPU (Thermoplastic Polyurethane) for the outer sheath. This is essential as these cables face continuous friction within drag chains. Standard cables may wear out quickly under similar conditions.

Oil Resistance: Given that drag chain cables often come into contact with oils, they are manufactured to resist oil degradation. Standard cables might not offer the same level of protection.

High-Frequency Bending Tests: Drag chain cables are tested for high-frequency bending to ensure they maintain performance over time. Standard cables may not undergo such rigorous testing.

Versatility: Drag chain cables generally outperform standard cables in terms of bending, pulling, and abrasion resistance, making them a better choice for applications with high mechanical demands.

While flexible cables may be cheaper, their shorter lifespan and higher maintenance requirements make them less cost-effective in the long run compared to drag chain cables, which, despite their higher initial cost, provide greater durability and reliability in demanding environments.

Contact: Mandy Dai

Phone: +86-13570383245

E-mail: sales@flex-cables.com

Whatsapp:0086-13570383245

Add: No. 12 building, No.46,Shilou Section,Shilian Road, Panyu District,Guangzhou, Guangdong,China

We chat