High flexing track cables also know as drag chain cable, drag cable, mobile cable, robot cable, flexible cable, etc. Particularly oil-resistant; chemical resistance; small outer diameter, saving the space required for cable installation; tinned copper wire braided shielding is easy to weld, and at the same time, it can ensure the transmission of data and signals without interference.

Product description of high flexing track cables :

High flexing track cables also known as drag chain cable, drag cable, mobile cable, robot cable, flexible cable, etc,which is Particularly oil-resistant; chemical resistance; small outer diameter, saving the space required for cable installation; tinned copper wire braided shielding is easy to weld, and at the same time, it can ensure the transmission of data and signals without interference.

Product Brand: Chengjia Cable

Specification model: TRVV Cable

Material: PVC or TPE or PUR

High Flexing Track Cables Structure:

Conductor: ultra-fine finely stranded oxygen-free copper wire

Insulation: Special mixed PVC or TPEInsulation sheath: high-quality nitrile mixture or PUR polyurethane

Shield: 80% tinned copper mesh braided shield or 75% copper mesh braided shield Color: black, gray or orange

Technical parameters of drag chain cable: Test voltage: 2500V-3000V Minimum bending radius:

Fixed installation: 5x cable outer diameter mobile installation:

When the stroke is less than 10 meters, the bending radius is 8xD. When the stroke is ≥10 meters, the bending radius is 10xD. Temperature range:

Fixed installation: -50°℃~+90°℃ Mobile installation: -30°℃~+90℃ can be specially produced according to your needs.

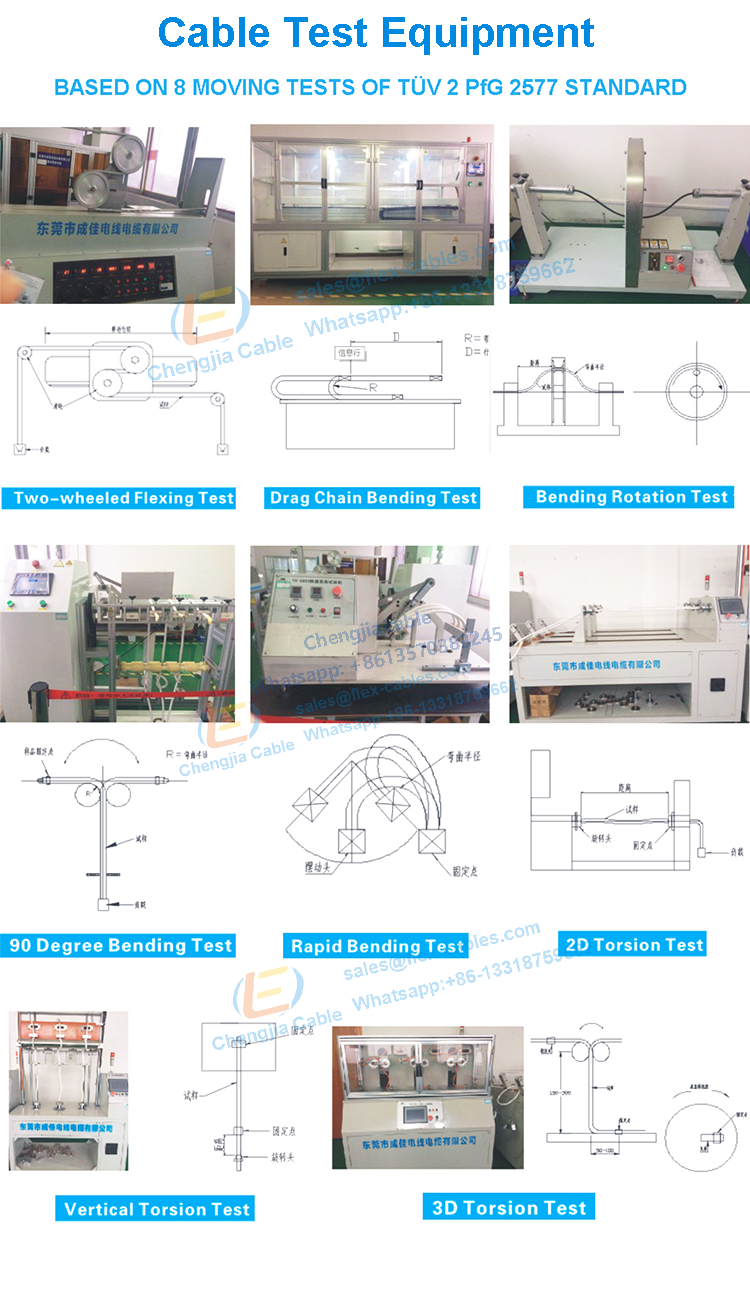

8 TEST machine for the High Flexing Track Cables

Test 1: the torsion of the double pulley (≤4mm2)

This test assesses the overall flexibility of the cable under the condition that the cable is subjected to radial tension and voltage and current loads are applied to the core.

Test 2: bending and rotating

In this test, the two ends of the cable are fixed, and the middle part does centrifugal rotation.

Test 3: bending

This is a cantilever that may be used to simulate a multi-joint robot. One end is fixed at the lower right corner and the other end is rotating. The bending speed is 20Oflexings/min, which is at least 30,000 times.

Test 4: bending of the drag chain

This test is a must-do item for drag chain cables, with a bending radius of 6D.

Test 5: 90 degree bending (>4mm2)

During the test, the cable free forging swayed from side to side within a range of 180 degrees, with a rotation rate of 40 times per minute, and the total number of times required was 1 million. Because the point of each bend is between the two fixed parts, and the operation is repeated at one point, this test is more demanding.

Test 6: 2D twist

There are two tests for 2D rotation, you can choose one of the two. One is horizontal, with a self-rotation at the left end, and the number of rotations determines an angle according to the needs of the customer. The second type is curve rotation, the left end is also fixed, and the right end rotates on the axis. Both test standards are at least 5 million times.

Test 7: vertical twist

During the vertical torsion test, there is a fixed end underneath. The angle of rotation during this test is relatively large, and the rotation speed is 12 times per minute.

Test 8: 3D rotation

The 3D rotation test is more complicated, similar to the 90-degree bending test, but the plate below needs to undergo a self-rotation, which is similar to the assessment in the 3D environment. A cycle needs to be rotated 360 degrees, and the rotation speed is 30 times per minute, at least It is 5 million times.

Contact: Mandy Dai

Phone: +86-13570383245

E-mail: sales@flex-cables.com

Whatsapp:0086-13570383245

Add: No. 12 building, No.46,Shilou Section,Shilian Road, Panyu District,Guangzhou, Guangdong,China

We chat